SCREEN PRINTING MACHINE

The semi automatic screen printer HS-SEL-E is designed for automotive/architectural glass processing.

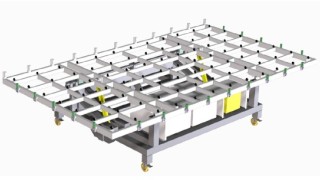

The operator load manually the glass and unload the glass by hand any different shape of glass on the blower printing table.

Vacuum system on the printing table guarantee fix position during printing process after fixed the printing position the glass by hand.

After automatically printing process, the printing head raise up and operator unload the glass manually directly in the dryer.

The screen frame is loaded / unloaded manually from the operator side, the squeegee and the flood coater pressure are adjusted from both side.

The printing head supported by four massive posts, perpendicular to the printing table is raised and lowered through a lifting mechanism.

Printer Standard features:

HS-SEL-E semi-automatic screen printing machine for automotive/architectural glass processing.

The operator manually loads the glass and manually unloads the glass of any different shape onto the printing table.

The suction system in the print bed ensures the fixed position during the glass printing process.

After the automatic printing process, the print head lifts up and the operator manually unloads the glass directly into the dryer.

The screen printing frame is loaded/unloaded manually from the operator side, the pressure of the squeegee and scraper is adjusted from both sides.

The print head supported by four massive uprights, perpendicular to the print bed, is raised and lowered via a lifting mechanism.

Standard printer features:

• Printing surface made of anodized aluminum equipped with suction device and air cushion

• Control panel: touch screen type;

• Horizontal position of the frame when applying the colour

• Print head equipped with anti-drip device: when the squeegee returns and the scraper is in operation, the squeegee rotates on the scraper to prevent drops of ink from falling on the frame